Unique, environmentally friendly waste recycling technology |

|

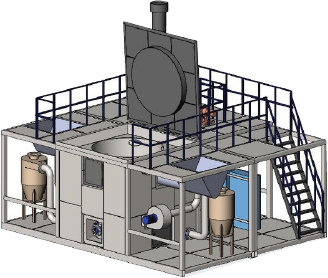

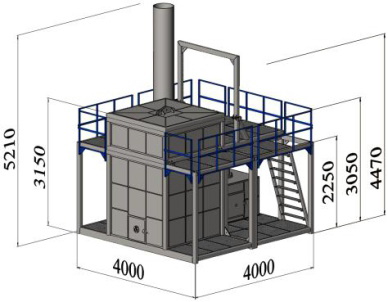

Features of the model SMSU - 5 for the treatment of municipal wasteBasic Information:

|

|

| 1255 |

| ||||||||||||||||||||||||||||||||||||

| 1256 |

|

Order No |

Carbon monoxide |

Nitrogen dioxide |

Ammonium |

Sulphur hydrogen |

Phenol |

Sulphur anhydride |

Nitric oxide |

Dust |

Concentration measured in the chimney (under normal conditions) |

||||||||

| 1 | 192 | 50 | 0,34 | 0,63 | 0,039 | 107 | 209 | 97 |

| 2 | 206 | 50 | - | - | - | 52 | 158 | - |

Near-ground concentration |

||||||||

| 1 | 0,10 | 0,025 | 0,000 | 0,00003 | 0,00002 | 0,053 | 0,104 | 0,048 |

| 2 | 0,11 | 0,026 | - | - | - | 0,027 | 0,081 | - |

Maximum permissible concentration (MAC) in the atmosphere in densely populated areas |

||||||||

| Not more than 1 time | 5,0 | 0,085 | 0,20 | 0,08 | 0,01 | 0,500 | 0,400 | 0,150 |

| Daily average | 3,0 | 0,04 | 0,04 | - | 0,003 | 0,05 | 0,06 | - |

Designation of the system |

MMSU-03 |

MMSU-05 |

MMSU-1 |

MMSU-2 |

MMSU-3 |

|

Capacity, m3 |

0,3 | 0,5 | 1,0 | 2,0 | 3,0 | |

Assembled overall dimensions:

|

|

|

||||

Degree of processing of raw materials,%, min. |

86 | 86 | 86 | 86 | 86 | |

Weight of mounted module, kg |

5 800 | 6 100 | 6 700 | 7 600 | 8 200 | |

Parameters of the power supply network:

|

|

|

|

|

|

|

MAX Total power consumption, W |

650 | 650 | 800 | 1 750 | 2 000 | |

Capacity, cubic meters per day max. |

3 | 6 | 12 | 24 | 30 | |

Time to reach operating mode, min |

45 | 45 | 45 | 45 | 45 | |

Operation |

Continuous, with occasional maintenance | |||||

Continuous operating time, h |

120 | 120 | 120 | 120 | 120 | |

Operating personnel, persons/shift |

1 | 1 | 1 | 1 | 1 | |

Temperature of the escaping gases C, max. |

265 | 265 | 265 | 265 | 265 | |

Instantaneous peak temperature of chemical conversion in plasma, C max. |

2 000 | 2 000 | 2 000 | 2 000 | 2 000 | |

Size of raw material chunks, mm |

up to 120 | |||||

Maximum permissible moisture of the raw material, % * |

50 | 50 | 50 | 50 | 50 | |

Hazard class of waste to be treated |

Hazard class 2 - 4 | |||||

Fuel |

Carbonaceous waste | |||||

*Further increase in moisture content leads to a decrease in the capacity of the plant. |

||||||

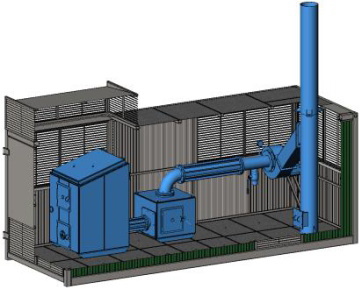

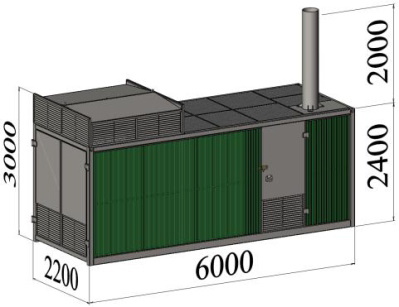

Designation of the system |

SMSU-4 |

SMSU-5 |

SMSU-6 |

|||

Capacity, m3 |

4,0 | 5,0 | 6,0 | |||

Assembled overall dimensions:

|

|

|

||||

Degree of processing of raw materials,%, min. |

86 | 86 | 86 | |||

Weight of mounted module, kg |

11100 | 11500 | 12300 | |||

Parameters of the power supply network:

|

|

|

|

|||

MAX Total power consumption, kW |

6 | 6 | 8 | |||

Capacity, cubic meters per day max. |

50 | 60 | 72 | |||

Time to reach operating mode, min |

45 | 45 | 45 | |||

Time to reach operating mode, min |

Continuous, with occasional maintenance | |||||

Continuous operating time, h |

120 | 120 | 120 | |||

Operating personnel, persons/shift |

1 | 1 | 1 | |||

Temperature of the escaping gases C, max. |

265 | 265 | 265 | |||

Instantaneous peak temperature of chemical conversion in plasma, C max. |

2 000 | 2 000 | 2 000 | |||

Size of raw material chunks, mm |

up to 600 | |||||

Maximum permissible moisture of the raw material, %* |

50 | 50 | 50 | |||

Hazard class of waste to be treated |

Hazard class 2 - 4 | |||||

Fuel |

Carbonaceous waste | |||||

*Further increase in moisture content leads to a decrease in the capacity of the plant. |

||||||